The transportation of heavy equipment for the construction industry as well as for the oil and gas industry can be very challenging for a TMS. To address these challenges, McLeod FMS software has introduced the Shipment Planning Module.

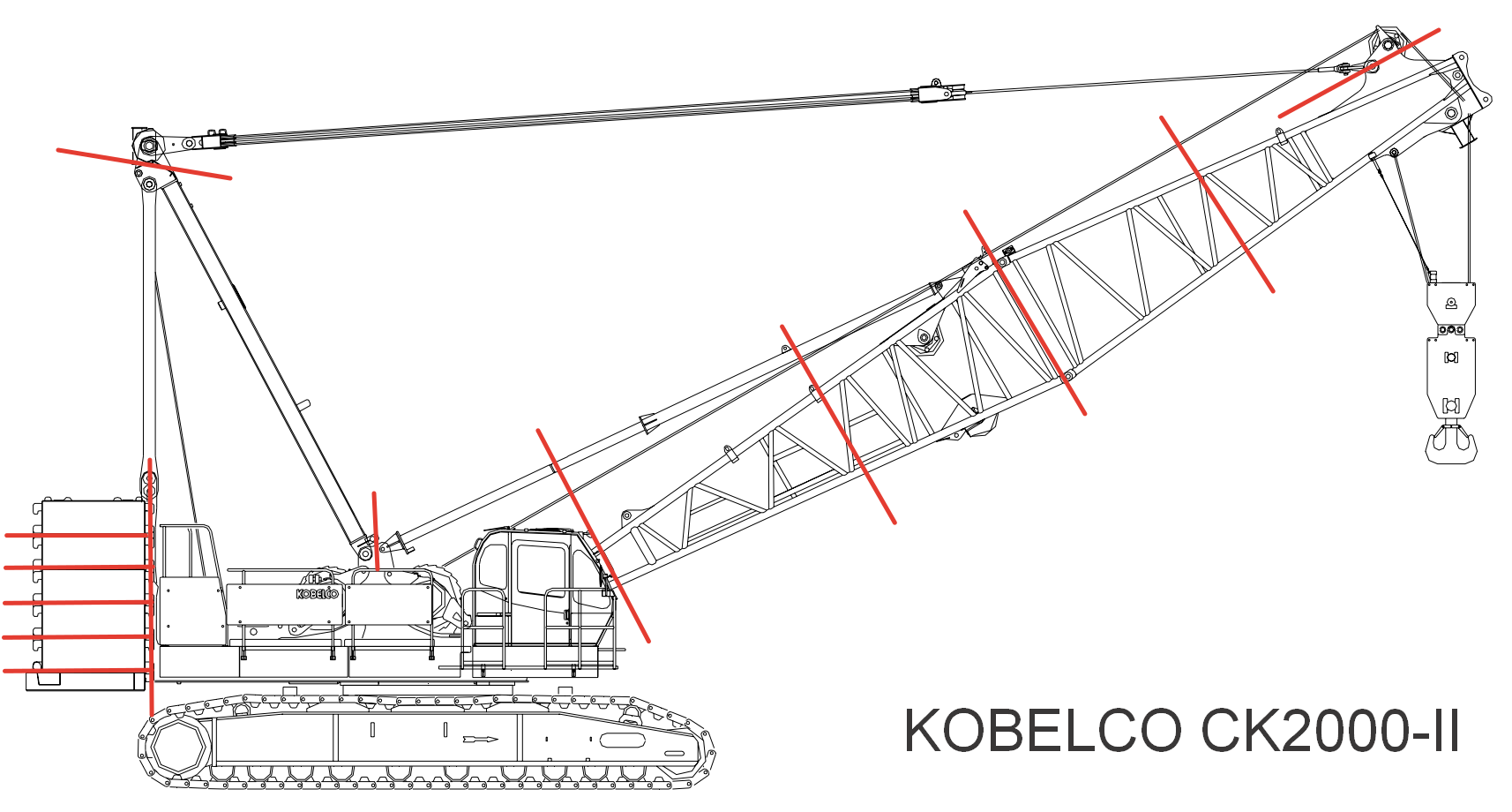

To illustrate some of capabilities of Shipment Planning, let’s use a crawler crane as an example:

The first challenge with transporting this piece of equipment is that the crane alone will take up one over-size truckload. Its boom and counter-weights will require another 10 flatbed trucks to transport. Larger types of equipment will of course require even more loads. Entering a dozen or more loads per piece of heavy equipment into a TMS can be quite complicated, time consuming and inefficient.

To add more complexity to the picture, imagine that the middle section of the boom was damaged during a previous job. As part of the shipment the damaged section of the boom must first be sent to a maintenance yard for repair. When the repair is completed it must then go to the construction site where the other parts have already been delivered. Since all the parts share the same serial number it is essential to track them together, even if they are not traveling together. The Shipment Planning Module allows you to manage all of the pieces even if they have different origins, destinations or stops and even when they share the same serial number.

The geographic location of a pickup or delivery site can also be a challenge for transportation. Construction sites often do not have an address, but rather a mileage point along a country road. Some sites may only have GPS coordinates. Transportation managers and employees in the field need to be able to provide accurate location information in a free form in order to refine this data later or match it to known location records.

Finally, when a shipment plan is ready for execution it is time to create loads and assign them to carriers. Many large equipment rental companies and construction companies have their own private fleets, and in some cases transportation can be facilitated using those resources. However, when there is not enough capacity with a private fleet, third party carriers will need to be considered and their rates evaluated.

The key piece holding the heavy equipment transportation process together from start to finish is the Shipment Plan. It can be compared to travel reservation for a family traveling by air from Houston to Seattle with a stopover in San Francisco. However, one member is joining the family with a direct flight from Chicago to Seattle. All of these itineraries will be under the same reservation number, though the itineraries entail different routes and may be using different airlines. When the time comes, the reservation turns into electronic tickets…or in case of a crawler crane Shipment Plan, into eleven Bills of Lading.

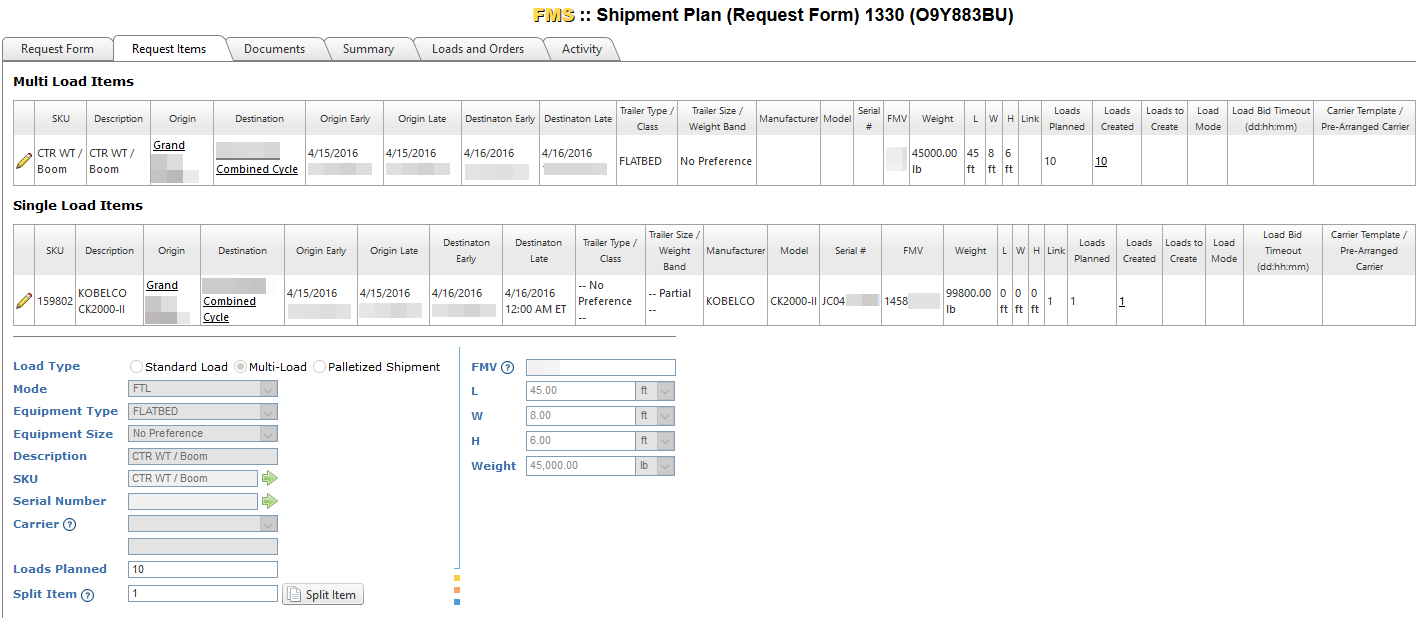

The process starts with a Requestor User completing a Request Form for a Shipment Plan. In the Request Form, the user enters as much information as they have at that moment, including any location information, serial numbers for the equipment, as well as photos or documents to help the dispatcher figure out the best way of splitting or grouping the shipment. The Requestor also has access to the Equipment Master, which lists the details of the equipment being shipped and allows users to look up the fair market value (FMV), equipment weight and dimensions.

When the Request Form is completed, the dispatcher has all the necessary information to determine which items fit on one truck and which must be split into multiple loads. It is then determined for each load whether it should be tendered directly to a private fleet, tendered to a pre-negotiated carrier or, whether it is to be sent out to a list of carriers as a Load Bid.

If the load is put up for bid, a pre-selected list of carriers will be contacted and asked to provide a flat rate through an automatic email. Bids are placed and the load is tendered to the carrier of choice.

At every step of this process notifications are issued to the parties involved ensuring that the requestor, the dispatcher, and the carrier are aware of the shipment’s progress or any changes. ERP API calls and EDI communications can also be enabled for parties that support them. Since the Shipment Planning module is part of McLeod FMS, which is a cloud-based solution, the information can be accessed on the internet from a computer or mobile device, even by users in the field.

We have worked closely with one of our customers who is a large equipment hauler to develop the Shipment Planning Module for their heavy hauling needs. It is this type of cooperative partnership that is vital to our strategy at McLeod Software for providing high quality products and services to the transportation industry. In the final analysis we are only as successful as our customers. With this in mind we make every effort to provide profitable software solution that save transportation companies money and help them succeed in providing efficient, quality service to their clients.

For more information on McLeod FMS please contact:

Cody Arnold,

Regional Sales Manager

Email: Cody.Arnold@mcleodsoftware.com

Office Phone: (205) 907-0983